The automotive industry stands at the precipice of a technological revolution that promises to fundamentally transform how vehicles are conceived, designed, manufactured, and maintained throughout their lifecycle. Digital twin technology represents one of the most profound paradigm shifts in modern automotive engineering, creating unprecedented opportunities for innovation while simultaneously introducing complex challenges that manufacturers must navigate with strategic precision.

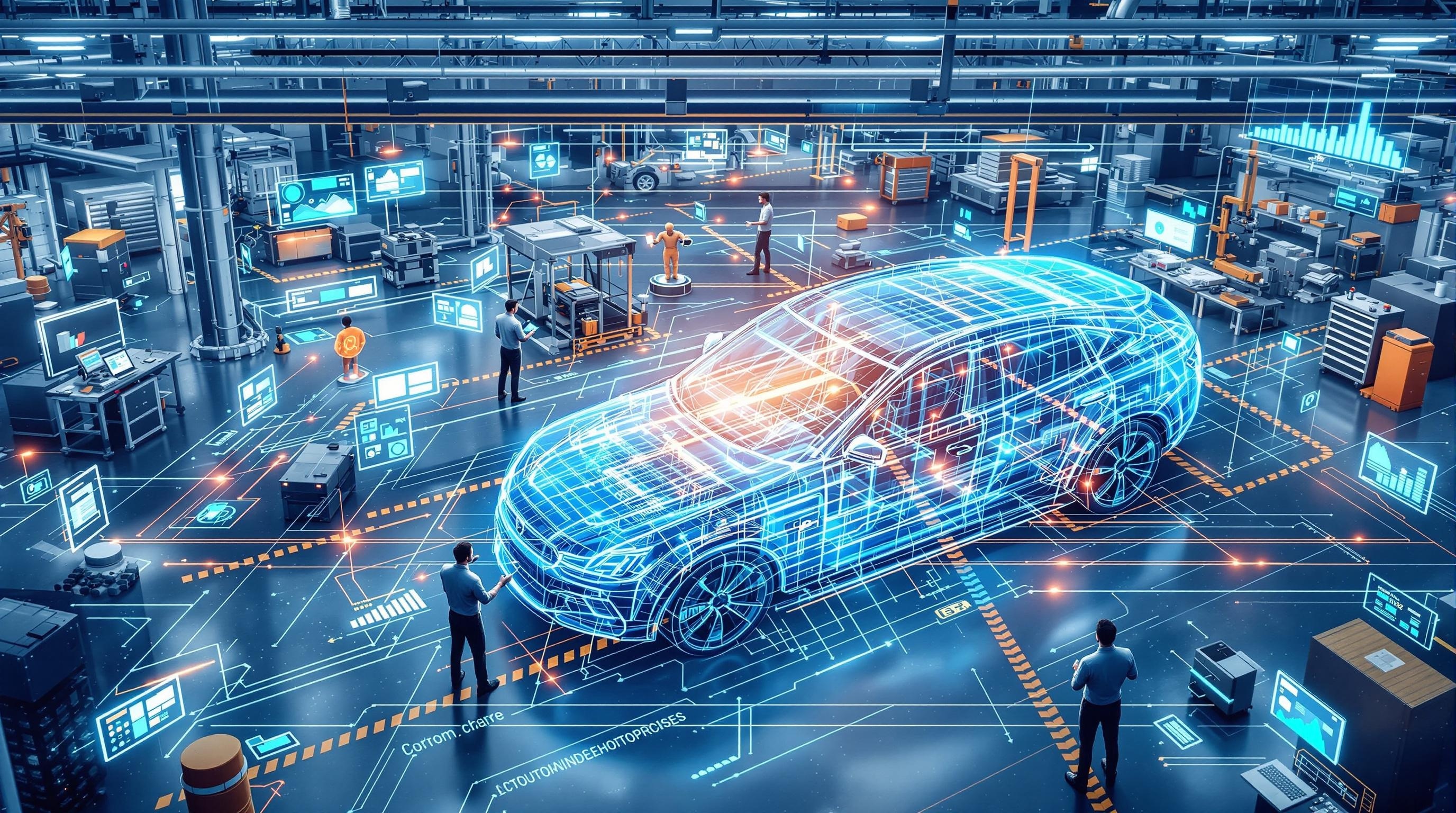

Digital twins in the automotive sector transcend simple virtual modeling or computer-aided design representations. They embody sophisticated, data-driven virtual ecosystems that mirror their physical counterparts with remarkable fidelity, creating dynamic relationships between the tangible and digital realms. This technology enables automotive manufacturers to harness the power of real-time data analytics, predictive modeling, and virtual experimentation in ways that were previously inconceivable.

The emergence of digital twin technology in automotive applications represents a convergence of multiple technological advances, including the Internet of Things, artificial intelligence, machine learning, cloud computing, and advanced sensor technologies. This convergence has created an environment where virtual representations can not only mirror physical vehicles but actively contribute to their optimization, maintenance, and evolution throughout their operational lifetime.

The Foundation of Automotive Digital Twin Technology

Understanding the foundational principles of digital twin technology requires examining the intricate relationship between physical automotive systems and their virtual counterparts. Unlike traditional computer models that remain static after creation, digital twins exist in a state of continuous evolution, constantly ingesting data from their physical counterparts and updating their virtual representations accordingly.

The automotive digital twin ecosystem operates through sophisticated sensor networks embedded throughout vehicles, manufacturing equipment, and production facilities. These sensors capture vast quantities of operational data, environmental conditions, performance metrics, and user interaction patterns. This data streams continuously to cloud-based platforms where advanced algorithms process, analyze, and integrate the information into comprehensive virtual models.

The sophistication of modern automotive digital twins extends far beyond simple data collection and visualization. These systems incorporate complex mathematical models that simulate physical phenomena such as thermal dynamics, aerodynamics, materials science, and mechanical stress patterns. By combining real-world sensor data with these theoretical models, digital twins can predict behavior, identify potential issues, and optimize performance with remarkable accuracy.

Machine learning algorithms play a crucial role in enhancing the predictive capabilities of automotive digital twins. These systems continuously learn from operational data, identifying patterns and correlations that might escape human analysis. As the digital twin accumulates more operational experience, its predictive accuracy improves, creating a self-reinforcing cycle of enhanced intelligence and capability.

The integration of digital twin technology with automotive manufacturing processes creates opportunities for unprecedented levels of optimization and quality control. Manufacturing digital twins can simulate entire production lines, identifying bottlenecks, predicting equipment failures, and optimizing workflows before physical implementation. This capability significantly reduces the time and cost associated with production line modifications and improvements.

Transformative Benefits Across the Automotive Value Chain

Digital twin technology delivers transformative benefits across every aspect of the automotive value chain, from initial concept development through end-of-life vehicle recycling. The comprehensive nature of these benefits creates compelling business cases for adoption while simultaneously driving innovation in unexpected directions.

Design and development processes experience perhaps the most dramatic transformation through digital twin implementation. Traditional automotive design cycles require extensive physical prototyping, testing, and iteration, consuming enormous amounts of time and resources. Digital twins enable engineers to conduct virtual testing and optimization throughout the design process, dramatically reducing the need for physical prototypes while simultaneously expanding the scope of testing scenarios.

The virtual testing environment created by digital twins allows automotive engineers to explore design possibilities that would be impractical or impossible to test physically. Extreme weather conditions, catastrophic failure scenarios, and long-term wear patterns can all be simulated virtually, providing insights that inform design decisions and improve vehicle safety and reliability.

Manufacturing optimization through digital twin technology extends beyond simple process monitoring to encompass predictive quality control and adaptive production strategies. Digital twins of manufacturing equipment can predict when maintenance will be required, allowing for proactive interventions that prevent unplanned downtime. Additionally, these systems can optimize production parameters in real-time, adjusting processes to account for variations in materials, environmental conditions, or operational demands.

The integration of digital twins with supply chain management creates opportunities for unprecedented visibility and optimization across complex automotive supply networks. Digital representations of suppliers, logistics networks, and inventory systems enable automotive manufacturers to predict and mitigate potential disruptions while optimizing costs and delivery times.

Customer experience enhancement through digital twin technology manifests in numerous ways, from personalized vehicle configurations to predictive maintenance services. Digital twins enable automotive manufacturers to understand how individual vehicles are used, allowing for customized service recommendations and proactive maintenance interventions that improve reliability and reduce ownership costs.

Real-World Applications Driving Industry Transformation

The practical implementation of digital twin technology across the automotive industry demonstrates the versatility and transformative potential of this approach. Leading automotive manufacturers have pioneered innovative applications that showcase the technology’s capability to address complex operational challenges while creating new business opportunities.

Tesla’s approach to digital twin implementation exemplifies the strategic potential of this technology. The company creates comprehensive digital replicas of every vehicle produced, continuously updated with real-world operational data from the vehicle’s sensor systems. This approach enables Tesla to monitor vehicle performance across their entire fleet, identify potential issues before they become critical, and deploy over-the-air updates that improve functionality and performance.

The Tesla digital twin ecosystem extends beyond individual vehicles to encompass their entire charging infrastructure network. Digital representations of Supercharger stations provide real-time monitoring of equipment status, usage patterns, and maintenance requirements. This comprehensive approach enables Tesla to optimize charging network performance while predicting infrastructure expansion needs based on usage trends and geographic analysis.

Renault’s implementation of digital twin technology demonstrates the potential for dramatically accelerating product development cycles. The company has reduced vehicle development time from traditional timelines measured in years to quarterly iterations through comprehensive virtual testing and optimization. Digital twins enable Renault engineers to conduct extensive virtual validation before committing to physical prototypes, significantly reducing development costs while improving final product quality.

Ford’s application of digital twin technology to lighting system development showcases the potential for addressing specific technical challenges through virtual simulation. The development of adaptive headlight systems required complex modeling of light propagation, reflection patterns, and driver visibility optimization. Digital twin technology enabled Ford engineers to simulate these complex optical phenomena virtually, accelerating development while ensuring optimal performance across diverse driving conditions.

Nissan’s “predictive digital twin” approach focuses on manufacturing optimization and predictive maintenance applications. Digital representations of production equipment and processes enable Nissan to identify potential bottlenecks and equipment failures before they impact production. This proactive approach has resulted in significant improvements in manufacturing efficiency while reducing unplanned downtime and maintenance costs.

Navigating Complex Implementation Challenges

Despite the tremendous potential of digital twin technology, automotive manufacturers face significant challenges in implementing these systems effectively. These challenges span technical, organizational, and strategic dimensions, requiring comprehensive approaches that address multiple interconnected issues simultaneously.

Data integration complexity represents one of the most significant technical challenges in automotive digital twin implementation. Modern vehicles contain hundreds of sensors and control systems, each generating data in different formats and frequencies. Integrating this diverse data into coherent digital twin representations requires sophisticated data management platforms and standardized communication protocols that may not exist across all vehicle systems.

The challenge of data integration extends beyond individual vehicles to encompass manufacturing systems, supply chain networks, and service infrastructure. Creating comprehensive digital twin ecosystems requires integrating data sources that may operate on different technological platforms, use incompatible data formats, or operate under different security and privacy requirements.

Cybersecurity considerations introduce additional complexity to digital twin implementation in automotive applications. The interconnected nature of digital twin systems creates potential attack vectors that could compromise not only virtual representations but also the physical systems they monitor and control. Automotive manufacturers must implement robust security measures that protect sensitive operational data while ensuring system reliability and availability.

The cybersecurity challenge is particularly acute in automotive applications because digital twins often contain sensitive information about vehicle performance, user behavior, and operational patterns. Protecting this information requires comprehensive security strategies that address data encryption, access control, network security, and incident response procedures.

Organizational challenges in digital twin implementation often prove as significant as technical obstacles. Successful implementation requires collaboration across multiple departments and functional areas, from engineering and manufacturing to information technology and cybersecurity. Establishing effective governance structures and communication protocols is essential for managing the complexity of cross-functional digital twin initiatives.

The cultural transformation required for successful digital twin adoption extends beyond technical training to encompass fundamental changes in how organizations approach problem-solving and decision-making. Traditional automotive engineering approaches emphasize physical testing and empirical validation, while digital twin methodologies rely heavily on virtual simulation and predictive modeling. Bridging this cultural gap requires comprehensive change management strategies and ongoing education initiatives.

Economic Implications and Strategic Considerations

https://drive.google.com/file/d/1hPxcasTtwu6VJQSoTW-i7EP3oojDK8gw/view?usp=sharing

The economic implications of digital twin technology in the automotive industry extend far beyond simple cost reduction or efficiency improvements. This technology creates opportunities for new business models, revenue streams, and competitive advantages that can fundamentally reshape industry dynamics and value propositions.

Capital expenditure optimization through digital twin technology enables automotive manufacturers to make more informed decisions about facility investments, equipment purchases, and infrastructure development. Virtual simulations of proposed changes allow manufacturers to evaluate potential returns on investment before committing significant resources, reducing the risk of costly mistakes while identifying optimization opportunities that might otherwise be overlooked.

The ability to conduct virtual testing and validation dramatically reduces the need for physical prototypes and testing facilities, creating significant cost savings in product development. However, these savings must be balanced against the substantial investments required for digital twin infrastructure, including data management platforms, simulation software, and specialized expertise.

Predictive maintenance capabilities enabled by digital twin technology create opportunities for new service business models and revenue streams. Automotive manufacturers can leverage digital twin data to offer proactive maintenance services, extended warranties, and performance optimization services that create ongoing relationships with customers while generating recurring revenue.

The competitive advantages created by digital twin technology often manifest in improved product quality, faster time-to-market, and enhanced customer experiences. These advantages can justify substantial investments in digital twin infrastructure while creating sustainable competitive moats that are difficult for competitors to replicate.

| Benefit Category | Short-term Impact | Long-term Transformation |

| Development Efficiency | 30-50% reduction in prototype costs | Complete virtual validation before physical production |

| Manufacturing Quality | 15-25% reduction in defect rates | Zero-defect manufacturing through predictive optimization |

| Service Innovation | Predictive maintenance capabilities | Autonomous vehicle health management systems |

Strategic considerations for digital twin implementation must account for the long-term evolution of automotive technology and market dynamics. The investment in digital twin infrastructure today must be compatible with future technological developments, including autonomous vehicles, electric powertrains, and connected vehicle ecosystems.

The Future Landscape of Automotive Digital Twins

The future evolution of digital twin technology in the automotive industry promises even more profound transformations as the technology matures and integrates with other emerging technologies. The convergence of digital twins with artificial intelligence, quantum computing, and advanced materials science will create opportunities that are difficult to envision with current technological limitations.

Autonomous vehicle development represents perhaps the most significant future application of digital twin technology in the automotive sector. The complexity of autonomous driving systems requires extensive virtual testing and validation that would be impractical to conduct solely with physical vehicles. Digital twins enable automotive manufacturers to simulate millions of driving scenarios, test edge cases, and validate system performance across diverse conditions and environments.

The integration of digital twins with quantum computing technologies promises to revolutionize the computational capabilities available for automotive simulation and optimization. Quantum algorithms could enable digital twins to solve complex optimization problems that are currently computationally intractable, opening new possibilities for vehicle design, traffic optimization, and resource allocation.

Electric vehicle development and optimization represent another area where digital twin technology will continue to evolve and provide increasing value. Battery performance modeling, thermal management optimization, and charging infrastructure planning all benefit from sophisticated simulation capabilities that digital twins provide. As electric vehicle adoption accelerates, these applications will become increasingly critical for automotive manufacturers.

The evolution toward connected vehicle ecosystems will further expand the scope and sophistication of automotive digital twins. Future implementations may encompass entire transportation networks, integrating individual vehicle digital twins with traffic management systems, infrastructure monitoring, and urban planning initiatives.

| Technology Integration | Current Capability | Future Potential |

| AI/Machine Learning | Pattern recognition and predictive analytics | Autonomous system optimization and self-healing vehicles |

| IoT Connectivity | Real-time sensor data collection | Ecosystem-wide intelligence and coordination |

| Edge Computing | Local data processing and response | Instant decision-making and autonomous operations |

Implementation Strategies for Automotive Organizations

Successful implementation of digital twin technology requires comprehensive strategies that address technical, organizational, and strategic considerations simultaneously. Automotive manufacturers must develop phased approaches that build capabilities incrementally while delivering tangible value at each stage of development.

The initial phase of digital twin implementation should focus on establishing foundational data infrastructure and developing pilot applications in controlled environments. Selecting appropriate pilot projects is crucial for demonstrating value while building organizational confidence and expertise. Manufacturing process optimization often provides an ideal starting point because it offers measurable benefits while operating in controlled environments with well-understood parameters.

Building internal expertise and capabilities represents a critical success factor for sustainable digital twin implementation. This requires not only technical training on digital twin technologies but also development of new analytical capabilities, data science skills, and cross-functional collaboration approaches. Automotive manufacturers may need to recruit new talent while simultaneously developing existing employees’ capabilities.

Partnership strategies play an important role in successful digital twin implementation, particularly for automotive manufacturers that lack internal expertise in advanced data analytics, cloud computing, or specialized simulation software. Strategic partnerships with technology providers, academic institutions, and consulting organizations can accelerate capability development while reducing implementation risks.

Change management considerations extend beyond technical training to encompass fundamental shifts in organizational culture and decision-making processes. Successful digital twin implementation requires creating environments where data-driven insights are valued and acted upon, even when they conflict with traditional experience-based intuition.

The integration of digital twin technology with existing enterprise systems requires careful planning and execution to avoid disrupting critical business operations. Automotive manufacturers must develop migration strategies that enable gradual transition to digital twin-enabled processes while maintaining operational continuity and system reliability.

Digital twin technology represents a transformative force in the automotive industry that promises to revolutionize how vehicles are designed, manufactured, and maintained. The benefits of this technology span the entire automotive value chain, from concept development through end-of-life recycling, creating opportunities for improved efficiency, quality, and innovation.

However, realizing these benefits requires addressing significant challenges related to data integration, cybersecurity, organizational change, and strategic planning. Automotive manufacturers that successfully navigate these challenges will gain substantial competitive advantages while contributing to the broader transformation of the industry.

The future evolution of digital twin technology in automotive applications promises even greater transformations as the technology integrates with other emerging technologies and expands to encompass broader transportation ecosystems. Organizations that begin building digital twin capabilities today will be better positioned to capitalize on these future opportunities while avoiding the risks of technological obsolescence.

The journey toward comprehensive digital twin implementation is complex and challenging, but the potential rewards justify the investment and effort required. Automotive manufacturers that commit to this transformation today will shape the future of transportation while creating sustainable competitive advantages in an increasingly digital world.

Technical Specifications Table:

| Implementation Aspect | Requirements | Considerations |

| Data Infrastructure | Cloud-native platforms with real-time processing | Scalability for millions of data points per vehicle |

| Security Framework | End-to-end encryption with multi-factor authentication | Compliance with automotive cybersecurity standards |

| Integration Architecture | API-first design with microservices approach | Compatibility with existing enterprise systems |

| Analytics Capabilities | Machine learning and AI-powered predictive models | Continuous learning and model improvement |

The automotive industry’s embrace of digital twin technology represents more than a technological upgrade; it signifies a fundamental reimagining of how transportation systems are conceived, developed, and operated. As this technology continues to mature and integrate with other emerging innovations, it will undoubtedly play a central role in shaping the future of mobility and transportation.

innovcar-tech.com

innovcar-tech.com